Runbay, as a professional rig manufacturer, gives customers the greatest convenience and sells spare parts for drilling rigs. During the long-term sales process, we found that the demand for drill bits and drill pipes is considerable, so in order to facilitate customers’ one-stop shopping, runbay offers customers a wide range of options, including drill bits and drill pipes of various specifications.

Drilling Bits

The drill bit is the main tool for breaking rock during drilling rigs. Whether the drill bit adapts to the nature of the rock and its quality plays a very important role in the selection of drilling technology, especially in terms of drilling quality, drilling speed and drilling cost. In the specific drilling work, scientifically select the drill bits and drilling pipes, thereby improving the working efficiency and quality of the drilling.

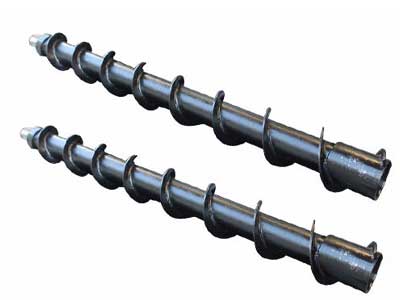

Drilling Pipes

The purpose of the drill pipe is to transport the drilling mud to the drill bit and to raise, lower or rotate the bottom hole device with the drill bit. The drill pipe must be able to withstand large internal and external pressures, distortions, bends and vibrations. The drill pipes body and joint are made of high-quality geological special alloy steel pipe, which greatly improves the fatigue strength and shear strength. It adopts advanced friction welding technology and CNC machining equipment, with features of high quality and stable production efficiency.

Geological Drill Pipe

DTH Drill Pipes

Geological Drill Pipe

Threaded Drill Pipes

Water Well Drilling Pipe

Water Well Drilling Pipe

Warm Tips of Matching Drilling Pipes and Bits

Under normal circumstances, the combination of our drill pipe and drill bit is that the diameter of the drill pipe is smaller than the diameter of the drill bit, because there are several advantages: 1. It is good for slagging; 2. The drill pipe is weak and not easy to wear; The effect of achieving hole formation is relatively good, etc. These are also based on our years of experience and experience.

Service Life of Drilling Pipes & Drilling Bits

Regarding the service life, it depends on whether the quality grade of the drill bit you are using matches the hardness of the rock layer you are drilling. For example, if you use a drill with a normal type of composite to drill a hard rock of level 10, it is completely impossible. It is defined by your geological conditions, rock hardness, and grade of composite.

Applications of Drilling Pipes & Drilling Bits

Related Drilling Rigs for Your Reference