As long as you order Down The Hole drilling rigs, you need pay attention to the operation methods before put it into use. This passage will instruct you how to operate rock drilling rig correctly.

1. Alignment

1) In case of special circumstances, the hole position deviation should generally not exceed 0.2 meters. The maximum is no more than 0.4 meters.

The holes and the row spacing and azimuth angles should be as uniform as possible.

2) Cut off the power of the traveling motor.

3) Switch on the working system power supply.

4) Move the main switch of the appliance console to the manual position. Remove the card wrench from the soldering bracket.

5) The drill is lifted slightly. Stop when the bit is about 30 mm from the ground.

6) Slowly lower the drill.

7) Install the dust cover

2. Open hole and DTH drilling

1) Start the exhaust fan.

2) Start the swing mechanism.

3) Pull the impactor control valve to the half open position.

4) Lower the drill. When the bit touches the rock, the lifting push mechanism lowering button is turned on. The impactor starts working and opens.

If a stuck or skew occurs, the drill should be lifted; repeat the above sequence until the impactor begins to drill normally.

5) Open or pull the impactor control valve to the proper opening position. According to the situation of the rock. Move the master switch to the automatic position.

6) Stop the drilling tool. Push the dominating valve handle to the pressure regulating position for pressure rock drilling.

7) If the rock is soft or broken, yellow mud should be placed in the hole to protect the wall.

3. Precautions for normal drilling

1) The temperature rises normally. Each motor shouldn’t have abnormal noise.

2) There is no noise during operation. The middle gear meshes normally.

3) Adjust the shaft pressure of the drill at any time, according to the rock condition at the bottom of the hole and the ammeter reading.

Prevent the crane from being overloaded. When the current exceeds the rated value, the drilling tool should be submitted immediately,

and the inspection and disposal should be completed before continuing the operation.

4. The axle pressure should be reduced when the carriage is severely oscillated.

5. Stop drilling when the air pressure is below 4 kg/cm2. No bridge pressure phenomenon.

6. The wire ropes of the lifting propulsion mechanism should be arranged neatly. The rope head is firm. You should always pay attention to adjusting the tightness of the wire rope.

7. When a stuck drill occurs to rock drilling machine, it should be disposed of according to the specific situation. Do not forcibly lift the drill pipe. In the case of thicker interlayers or water in the holes, it is necessary to first drill and then stop the wind to avoid clogging the impactor.

8. When the wind pressure suddenly drops, the impactor does not ring. The cause should be identified and disposed of in a timely manner. In order to avoid overload or break the wire rope and other accidents.

9. The limit switch that pushes the cylinder block should always be flexible and effective.

High security, high economy, high reliability from RUNBAY MACHINERY!

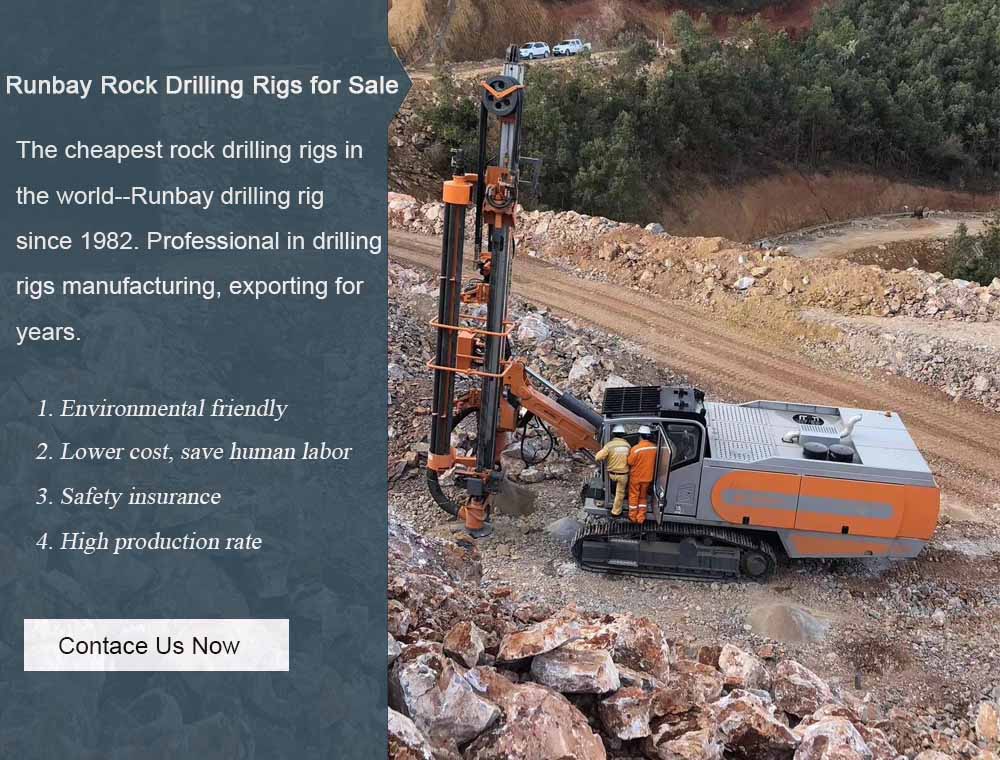

Runbay DTH Rock Drilling Rig Had Been Sold to Nigeria

Nigeria customer know Runbay from his business partner, who is Runbay regular customer. From the drilling needs and geological conditions, our engineer recommend him RB 450, which is ideal choice for air open pit qurries, and varies bench excavation projects with medium soft and hard rocks, blasting and drilling projects. This customer received his drilling machine within 30 days, cause we have stock in factory, as soon as he received, he took some working pictures for us, and gave highly praise to Runbay machine. If you want have your own drilling plan, pls send email to us: sales@runbaydrillingrig.com,we will provide you the most suitable project design.