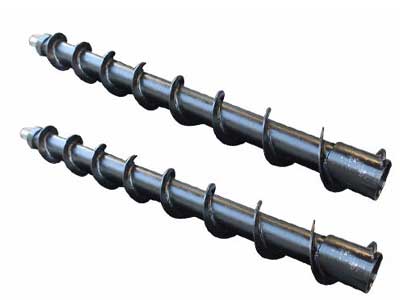

1. When using the new drill pipe, it should be determined that the thread of the front end of the drill bit (protecting the shaft head) is also close to the turn of the new one. It is easy to damage the thread of the new drill pipe, causing water leakage, buckles and looseness.

2. When using the drill pipe for the first drilling, you should “grind the new buckle” at first. The detail steps is applying the threaded oil, then use the drill to fully tighten, then open the buckle, thread oil again. This is repeated three times to avoid new wear and buckles.

3. As far as possible to maintain the drill pipe in the ground and under the ground is straight, so as to avoid the side of the threaded part of the force and cause unnecessary wear, and even jump buckle. It is very important to pay attention to anchor the drilling machine to avoid the force of movement during construction.

4. When tightening the buckle, you should tighten slowly to reduce overheating and wear.

5. Each time you buckle, you must tight it, and pay attention to the state of the clip is good on time.

6. Shorten the distance that the rig is poured into the ground, because if the drill pipe lacks support, the drill pipe will be easily bent and deformed when it is guided, resulting in a shortened life.

7. Keep the inlet angle as small as possible, and slowly change the angle according to the safety requirements of the drill pipe.

8. Do not exceed the maximum bending radius of the drill pipe. Pay special attention to changing the horizontal section during drilling and changing the angle of the drill into the drill.

9. Keep the drill pipe in turn to avoid the fixed drill pipe from guiding and retracting. It must be rotated to avoid excessive wear and break the rod.