RUNBAY Truck mounted borehole drilling rig since 1982, our products are of superb quality and the typical oriental make-up. we have a national patent for borehole drilling machines, exported over 1000 sets last year. Trcuk mounted Water well drilling rig is more prevellent in Africa, cause it can be moved very easy. For the water well drilling rig, what the most concer is whether the promise depth is reach or not. For more Details pls contact Runbay Team: sales@runbay-machinery.com

No.1 Truck mounted water well drilling Manufacture in China, we are the only certification and license to product the truck mounted water well drilling rig, introduced the core technology from Atlas Copco, make each component has their own optimized process capability and they are interconnected with each other to impact the overall performance. Another good point is that borehole drilling machine price is very afforable, using our rig, you will also notiece a significant annual saving in fuel consumption as well. Following is the The Nine Core Technology of RUNBAY Truck Monted Borehole Drilling Rig:

1. All-terrain Off-road chassis, multi-axle steering and multi-steering mode that provide flexible steering, Hydro-pneumatic suspension with a good travelling performance, which adapts severe road conditions such as muddy road, sand, snowfield, upland, etc

2. Full hydraulic top-drive, which effectively reduces the wearing of the drill stem thread, and increases service life of the drill stem. A spindle with strong slag discharge capacity through large drift diameter, which makes it especially adapt the reverse circulation construction.

3.A feeding system with a large stroke, which adapts to long drill stem and long casing constructions and retracts when travel to reduce transportation dimensions.

4. Convenient stem changing mechanism,

5. The advanced and efficient hydraulic control system.

6. Efficient large torque fastening and unfastening device,

7. Capacity to drill 0-1000 meter depth with 500mm diameter

8. Types of Common Drilling Systems

9. Rotary mud and DTH drilling systems are the most common well drilling method in Ethiopia. While mud rotary is widely used for soft and medium formation soil where substantial overburden exists, DTH system is usually employed for faster drilling on medium and hard soil including rocky formations.

What is the Diesel Engine Brand for the Rig? what about the oil pump?

—The Enginer Brand we adopted are the Yuchai Industrial modle( Under 600 Model) and the Commins Diesel Engine (above 600 Model);

The Yuchai Industrial Engine more powerful force compared with the Cival level;

For example: same 110kw, the Industrial level engine power force can reach larger than 110kw, the Cival level’s 110kw will be the limit valve;

—For the oil pump, we adopted is the German Brand Permco Oil Pump and Italy Brand CASAPPA , with features of small engine, low fuel consumption and high efficiency;

2. What is your main advantage in performance compared with others?

— For Mechanical machine, especially for the Drilling Rig, it is the core parts of the machine that decide the machien overall performance. Core parts as follows:

(1) Oil Pump & Diesel Engine: They are 2 very core parts that decide the machine performance directly, and in drilling market, there seems have a misunderstanding, the bigger diesel engine is better.

Actually, it is not true, There is a Golden Ration for the Oil Pump & Diesel, generally the Diesel Engine with bigger Power around 20-30% than the Oil Pump can perform it’s best performance and power force.

Otherwise, it will cause more oil consumption, but didn’t take performance for the machine working.

(2) Power Unit: The power unit drives the principal axis to rotary movement, it belongs to sophisticated products very critical part for the overall performance:

<1> We adopt the America Eaton Brand Rotary Motor, with Low speed and high torque, to provide powerful rotary force for the Drilling Rig.

<2> For the Rotary Motor, only the experienced workers at least with 5 years experience allowed do this part, to make sure the matching among different bearings quick-proof and oil tight.

(3) Hydraulic Operation Station: This station controls the full set machine, every part or move need to operated here.

<1> Most important part of Station is the valve element, controls the whole machine, the adopted is the German Brand Sun, the valve element what do is the best quality and performance.

<2> Another important is that the operation station need to be quick – proof and durable, since when water rig drilling wells, it will have strong shakness.

We adopt the High Tense Folding Design Operation Station, it is our factory’s patented design, with strong tense, quick proof and more durable, very different than the common station.

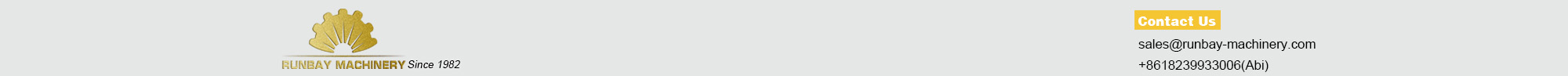

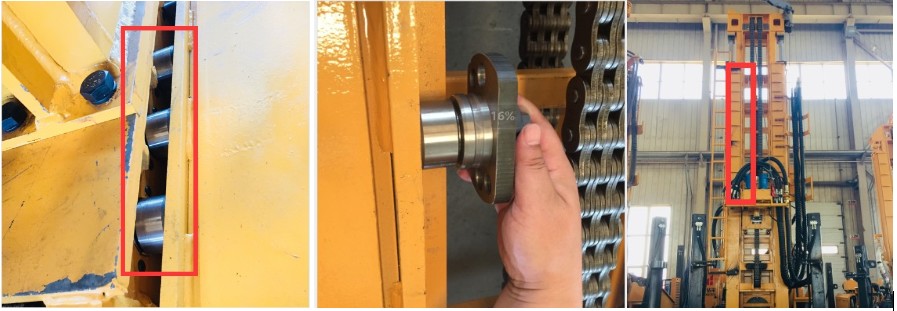

(4) Friction Design of the Slide Block: Since water rig will produce strong and large frictions during work in the slide Block, so we need to minize the frictions.

Generally in the market, most manufactures adopts the sliding friction, but in order to minize the frictions, what we adopted is the Bearing rolling frictions as follow pics.

3. Which part need to do the maintenance?

—As we all know, the performance of the Rig itself very important, second important is the maintenamce, it directly decide life service of the machine.

Main parts need to maintain: The Hydraulic Oil cylinder, filter element, seals. need to maintain regularly, we have clients who maintained very well, the Hydraulic system have used 15 years.

We will have the Detailed Manual Operations to help instruct how to maintain and time to maintain, pls rest assurred about this.

4. Does the Truck will be powerful force when carrying the Rig?

—-Yes, this is for sure, powerful force. We make sure the powerful force of the Truck Mounted Rig from following aspects.

(1) From the Truck Choice, our engineers will help choose the most suitable and high performance Truck Model as per clients Drilling Requiements and the Bearing force those parameters.

(2) Every set of our Truck Mounted Drilling Rig, we will add more extra pics of steel plates under the Truck, to improve the Bearing force and the shock absorption of the Truck Rig.

(3) last but not the least, In the Truck Drilling Market, most manufactures also some South Africa and India designed Truck Mounted Drilling Rig, the Drilling Rig and Truck share one common Disesl Engine.

<1> Considering the TPO System not very mature in the whole international market, this kind of design will cause the reduction gears more easily to occur issues, and for the reduction gears

can only to replace a new one once broken, the cost need around 10,000-12,000USD, maintenance costs later will be more extra costs.

<2> In order to avoid this situation, our engineers developed and designed the Truck Mouted Drilling Rig with seperate Engine system for Truck and Rig, each unit have it’s standard engine.

This kind of design not only powerful force for each unit, but also more durable for the full set machine, save the labore maintenance costs.

Contact us today and let us know how we can help your business succeed!